Sustainability at DWI

Nowadays, we encounter the term sustainability incessantly in everyday life. Whether in the field of agriculture and its products, clothing or mobility - all areas should and must eventually become more sustainable in order to keep up with the challenges of the ever-worsening climate crisis and to avert environmental disaster. The demand for sustainability is also increasing in research: Can we smartly reconcile technological advances and sustainable objectives? How can we develop high-performance materials for daily use in a resource-saving manner? How can we combine efficient agriculture with sustainable crop protection agents?

Our researchers at the DWI - Leibniz Institute for Interactive Materials work on these and related questions daily. To introduce our projects and ideas to the public, we present some of these projects which are aiming for a common, more sustainable future in our new thematic series "Sustainability at the DWI". The following paragraphs describe two of our projects that have already enabled major steps towards more sustainable solutions for acute ecological issues of our modern society.

greenRelease technology

Many crop protection products have an inherent weakness: the agents do not adhere sufficiently to the plants, are washed off by rain and seep into the soil. As a result, not only protection is lost, but soils and groundwater are also severely polluted. In addition, costly and laborious reapplication of the protective agents is necessary to maintain the protection and the resulting yield.

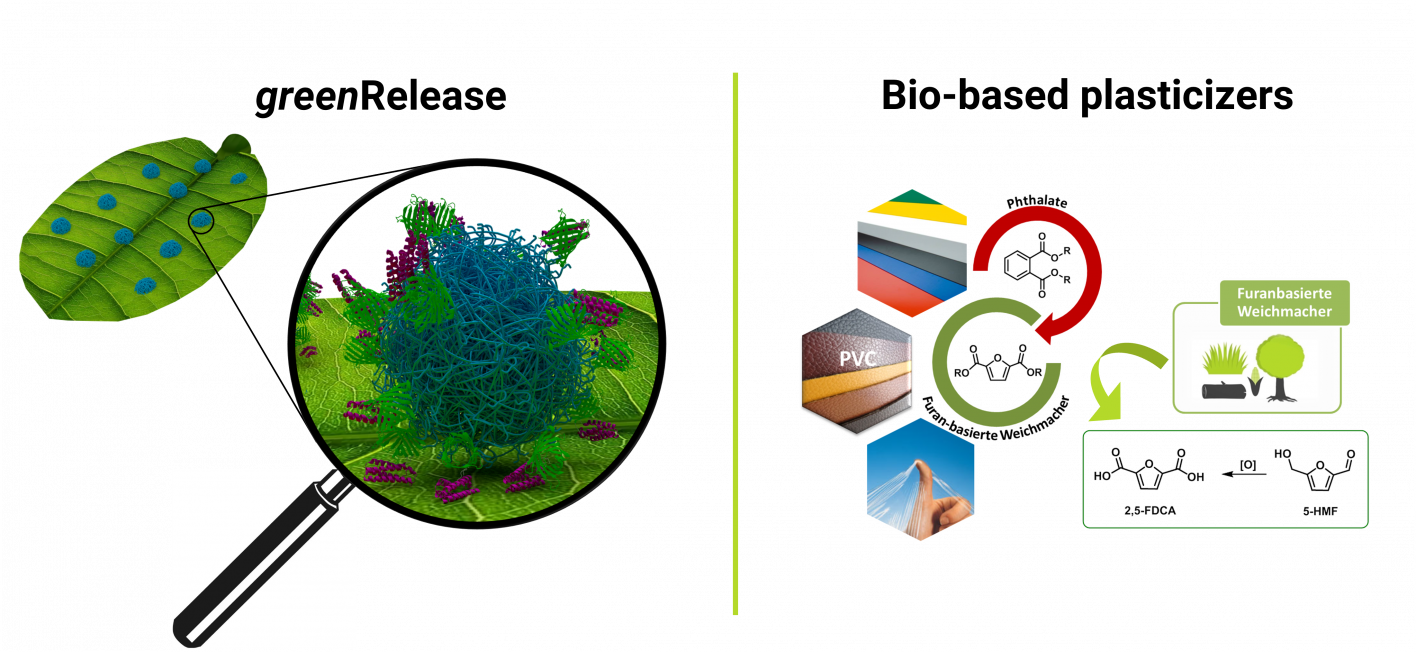

To minimize the active agents used to protect the crops in the future, the greenRelease technology has been developed. The working groups led by Andrij Pich and Ulrich Schwaneberg have combined their expertise in this novel technology and developed "microgel containers" that are bound to the plant in a rainfasten manner via special anchor peptides. The soft and porous polymer colloids have binding sites inside and thus enable controlled release of the active ingredients. The overall objective of the project was to demonstrate that the same crop protection can be achieved with a significantly reduced amount of agent compared to currently used products.

As part of the finalized greenRelease project, which was funded by the Bioeconomy Science Center, customized anchor peptides were identified and optimized in the laboratory, enabling the microgel containers to bind rainfasten to apple and sugar beet leaves. The microgel containers enabled controlled release of the pesticide over a period of weeks. In the final year of the project, a sufficient quantity of the greenRelease formulation was produced to put the technology through its paces for apple cultivation in field trials conducted by the North Rhine-Westphalia Chamber of Agriculture. The tests showed that the use of contact fungicides could be reduced to one-third utilizing the greenRelease formulation. In addition, microorganisms capable of potentially degrading the utilized microgel building blocks were identified, so that leaving any residues in nature could be avoided. In contrast to conventional and commercial protectants, which quickly lose their effect due to rain, the greenRelease technology thus offers three decisive advantages: high rain resistance due to adhesion to the plant, good plant compatibility and adjustable biodegradability.

Alongside the technical development work, the market potential of the greenRelease technology was also evaluated. To this end, we discussed the advantages of our technology with industrial partners from our Technology Transfer Advisory Board as well as with other partners along the value chain, such as agricultural suppliers, and developed a business plan. The business plan was submitted to the Bio-Security GmbH's Biogründer-Wettbewerb 2019 and presented to an expert jury in front of more than 100 guests from science, industry and politics. We were able to prevail against strong competition and achieve the first place.

The project, funded by the Ministry of Culture and Science of the State of North Rhine-Westphalia, was led by Felix Jakob from Ulrich Schwaneberg's working group, in which scientists from various research areas collaborate with other research facilities and institutions. Based on these technology modules, further DWI projects such as "ProPlanta", "proSeed", "InFuProts", "EcoGuard" and "hoRtikulturNA" were initiated. In these projects, the technology is applied to reduce the use of pesticides or to avoid the use of microplastic-containing formulations in agriculture. If successful, the developed strategies and technologies can contribute to a more sustainable agriculture and bioeconomy.

Bio-based plasticizers

The DWI is also working on sustainable solutions in other fields: Polyvinyl chloride (PVC) can be found in a wide range of products in the fashion, sports, housing and automotive sectors, for example in the form of resilient floor coverings, artificial leather or upholstered furniture. Plasticizers, including phthalates in particular, are used to ensure the flexibility of these products. The phthalates are essential for turning the inexpensive but brittle mass plastic PVC into flexible and stretchable materials with highly variable, product-specific properties.

Phthalates belong to the group of low-volatile organic compounds, are not strongly bound in soft PVC and can thus slowly and permanently evaporate from the product. This causes serious environmental consequences in the case of several phthalate compounds - for instance, they can get into wastewater, fields or groundwater via detours, where they cause serious environmental damage to flora and fauna or to sediment. Furthermore, some phthalate compounds are considered hazardous to humans and are therefore even banned in various products. In addition, they are produced from petrochemical raw materials such as crude oil, whose finite availability is not only a major problem, but makes the use also controversial from an environmental point of view.

Last but not least, the negative image of phthalates among consumers has driven the development of bio-based and sustainably produced alternative plasticizers. Existing bio-based plasticizers, such as epoxidized fatty acid esters or carbohydrate-based plasticizers, such as succinic or citric acid esters, each have advantageous properties that make them suitable for use in flexible PVC products - mostly niche applications. However, they lack the "universality" of application possibilities known from phthalates. Furan esters, on the other hand, have a similar structure and polarity compared to conventional phthalates and thus represent a promising alternative.

The suitability of furan-based plasticizers as universal or specific substitutes for phthalates in flexible PVC applications has been investigated by the DWI in the working group of Martin Möller in cooperation with the Institute of Technical and Macromolecular Chemistry at RWTH Aachen University and the Research Institute for Leather and Plastic Sheeting gGmbH (Freiberg).

In the joint project, the team conducted research into sustainably producible furan and tetrahydrofuran derivatives. The central subject of the investigation were different derivatives of 2,5-furan dicarboxylic acid, which can be considered as a biomass-based alternative to phthalic acid. The aim of the work was to develop a plasticizer library and to establish an application-related knowledge base. A total of eleven different furan- and tetrahydrofuran-based plasticizers were synthesized in the project. The plasticizers were investigated with regard to their effect on thermal and mechanical properties of PVC plasticizer blends. Selected plasticizers were then tested for their performance and application potential for soft PVC coated textiles. In the end, two furan-based ester plasticizers were identified that exhibit similar properties as the reference plasticizer DINP (diisononyl phthalate), which belongs to the phthalate group. The properties of these ester plasticizers were then tested and subsequently confirmed for use in the production of synthetic foam leather and banner material.

The project, which was funded by the German Federal Ministry for Economic Affairs and Energy (BMWI), identified appropriate solutions for more sustainable production of flexible PVC. The researchers have succeeded in producing furan-based plasticizers for the substitution of phthalates in PVC-based textile coatings, which can make the production of flexible PVC more efficient, sustainable and resource-saving in the future.

We look forward to sharing further sustainable projects with you in our new themed series in the future! To implement all these projects, the DWI – Leibniz Institute for Interactive Materials is working hand in hand with other research institutions and project partners around the world, because one thing is for sure: challenges of such magnitude cannot be tackled by anyone alone but require the expertise of a multitude of parties whose common goal is a more sustainable future.