Is it possible to stimulate the formation of new damaged cartilage tissue in the body, and if so, how? This is the question addressed by the TriggerINK project, which is funded by the Werner Siemens Foundation. In the following, we explain in detail what the work in the project looks like and what challenges need to be overcome.

Hydrogels as Matrix for Cells

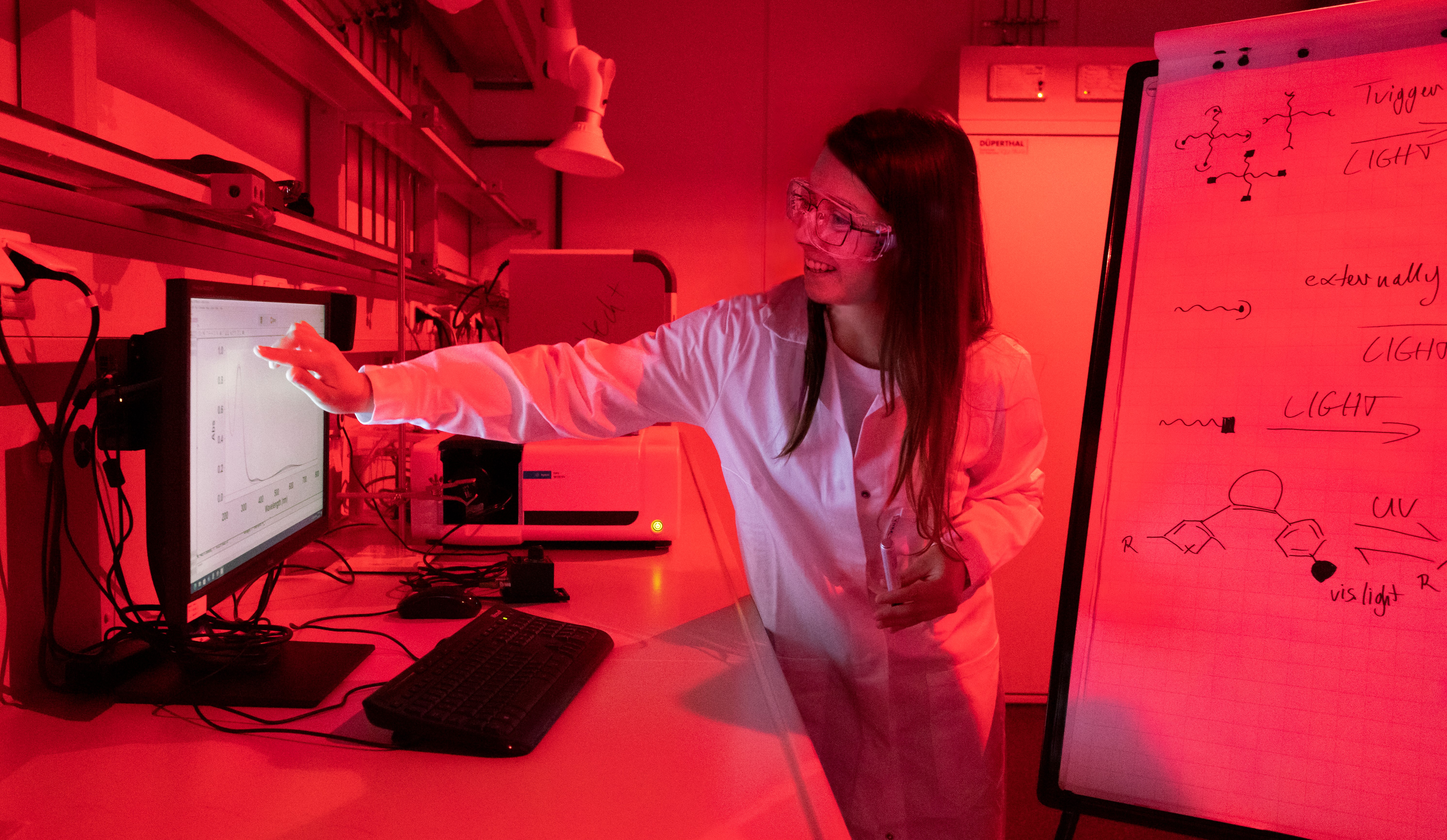

For the replication of cartilage tissue, the cells need a supporting scaffold, which for the TriggerINK project is based on a hydrogel. We want to take a new approach with the gel we have developed: Our scientists are working on an innovative composition that cross-links when irradiated with light of a specific wavelength, forming a 3D-printed support scaffold. This hydrogel is combined with three components that independently support cell growth differently.

Magnetic Microparticles as Physical Stimulus for Controlled and Structural Cell Growth

The natural structures of cartilage have different orientations and thus functions depending on their position in the tissue. For example, they enable frictionless gliding on the surface or have cushioning properties inside the cartilage. The goal of the TriggerINK project is to reproduce these different structures. To do this, the team uses a method developed at the DWI: the alignment of microscopic, rod-shaped elements in the supporting gel-like framework materials using a magnetic field.

The magnetic nanoparticles contained in the micro-rods react as soon as a magnetic field is applied. In other words, using a magnet during the polymerization of the gel scaffold, the rod elements rotate and orient themselves parallel to the direction of the magnetic field. This way, the various structural orientations in natural cartilage can be mimicked. In the TriggerINK project, we investigate different production methods for magnetic rods and their effect on the growth of chondrocytes and the regeneration process of cartilage tissue.

Ultrasound-responsive Microparticles for the Release of Chemical, Biologically Active Agents

Another part of the TriggerINK kit is developing an ultrasound-responsive system for the targeted release of biologically active substances such as growth factors. These substances will be integrated into the bioink, allowing a retarded release of various growth factors at different times during the regeneration phase of the cartilage. The retarded release is intended to promote cell growth and suppress and specifically influence the body's immune response. From a chemical perspective, the growth factors are inactivated by being bound to adapted DNA polyaptamers. These bonds can be loosened by ultrasound stimulation, and the growth factors can thus be released and reactivated. With the help of this technique, spatial and temporal control of the healing process should be possible.

Pulsating Microparticles as Mechanical Fitness Promoters of Cells (in-vivo Gym)

The “in-vivo Gym“ particles are designed to shorten the healing time until the start of conventional rehabilitation after the ink is printed into the wound. The idea is to activate local cell regeneration in the cartilage and begin training at the microscopic level before rehabilitation can start. The particles can be activated externally with harmless infrared light, penetrating deep into the affected region. Pulsing the light causes the particles to contract and expand back to their initial size at regular intervals. The resulting mechanical stimulation activates the surrounding cells and influences their growth and regeneration properties.

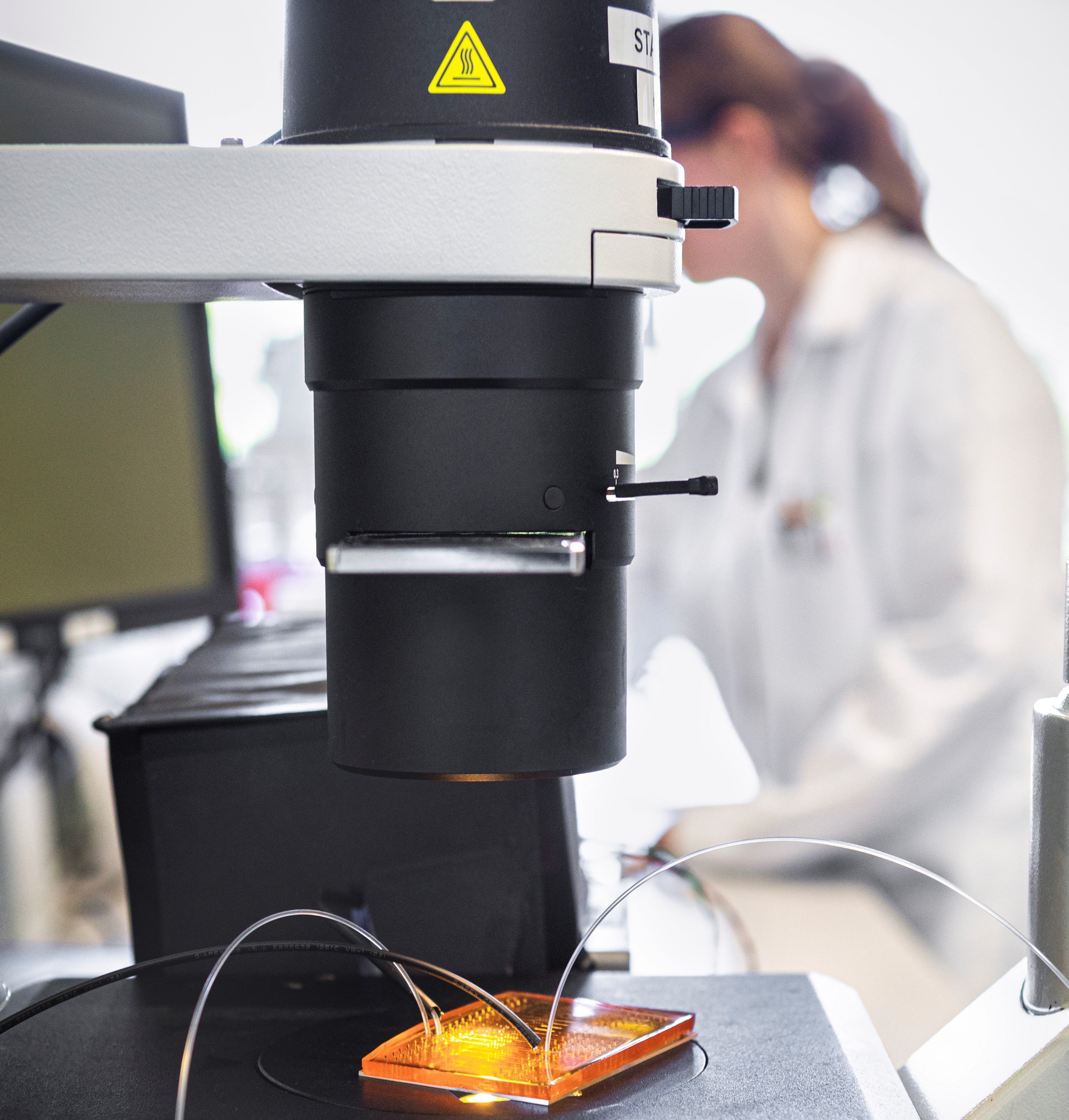

Robot-assisted 3D Printing Directly in the Wound

Ultimately, the components developed in TriggerINK must be inserted into the knee wound. TriggerINK aims to use a robot that recognizes the wound with depth sensors and creates a digital model. A 6-axis robot arm allows movements and positioning of the print head according to the wound position with preciseness and resolution superior to human abilities. Once positioned, a specially engineered print head, mounted at the robot's top, will inject and polymerize the hydrogel directly into the wound following an in-vivo 3D-printing approach.